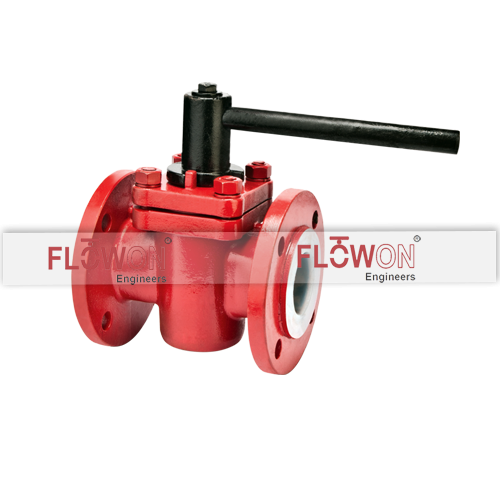

Lined Plug Valve

Lined Plug Valve

‘FLOWON’ FEP/PFA lined Plug valve is professionally designed and manufactured for superior performance as per international standards API 599. Basically a Plug valve is a Quarter turn valve similar to that of ball valve, which has cylindrical plug inserted in the soft sleeve that is rotated to control the fluid flow. The Three level Sealing (Sleeve Sealing, Line sealing and diaphragm sealing) of plug valve makes it favourable choice for highest sealing capacity as compared to other conventional valves (Ball Valve, Butterfly valve etc). Plug valve Body consist of One piece design, internally ribbed to provide superior strength to the body structure. Plug designed by ‘FLOWON’ experts are One-piece, Heavy duty and Investment casted. The lining material used is FEP (Fluorinated Ethylene Propylene) or PFA (Perfluoroalkoxy) , an inactive plastic compound which offers excellent anticorrosive properties. ‘FLOWON’ has in house 3 nos heavy duty plastic injection moulding machine which makes easy to maintain the quality of lining. FEP/ PFA granules used by us is of Japan / Korean origin. To ensure perfect gripping and to prevent the liner Breakdown, the liner is perfectly locked in to the Dovetail groove in the Body casting and Holes in Plug casting. The machining of Plug/stem after lining is done by CNC machine to ensure high precision machining.

SALIENT FEATURES

- Due to its Compact design, very less component required for construction of valve.

- Unlike ball valve, there is zero cavity between plug and lining which in turn eliminates contamination and Sticking of media on plug.

- ‘T’ handle provided for easy operation of valve

- ISO 5211 mounting pad arrangement is provided for easy installation of Electric / Pneumatic Actuator

- Allen bolts are inserted in to the bottom to maintain the orientation of Plug.

PRODUCT RANGE

- Size:- 1” to 8”

MATERIAL SPECIFICATIONS

- Body:- ASTM A 395 Gr. Ductile Iron

ASTM A 216 Gr. WCB

ASTM A 351 GR. CF8 / CF8M - Plug & Stem:- Stainless Steel (FEP / PFA lined)

- Seat & Seals:- P.T.F.E

TECHNICAL SPECIFICATIONS

- Design Standard:- API 599

- Testing Standard:- BS EN 12266-1

Hydrotest:- 16 kg/cm2 (Body) 12 kg/cm2 (Seat)

Air Test :- 6 kg/cm2

Spark Test:- 20 Kv D.C - Drilling Standard:- As per ANSI B 16.5, 150#

- Face to Face Dimensions:- ANSI B 16.10

- Lining Thickness :- 3.0 to 5.0 mm