Angle Seat Valve

Angle Seat Valve

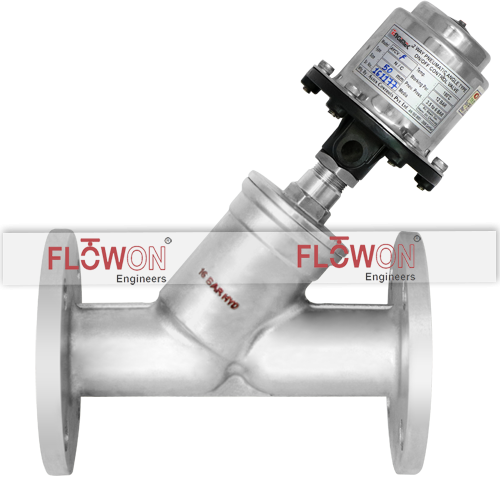

Angle Seat Valve Offered by “FLOWON” is an Excellent alternative to Ball Valves where longer Service life operation is required. Our Angle Seat Valve is suitable for as many as 5 million of Working cycles in various applications such as Water, Gas, Stream and Oil. The body Construction of Angle Seat Valve is same as that of ‘Y’ Globe valve, but in Angle Seat Valve, a piston is used instead of plug which sets on a PTFE seat. It is also considered as best choice against the Solenoid valve which fails on highly contaminated working media.

Depending upon the Piston operation, Angle seat valve is

classified in to 3 Types

- Normally Open: In Normally open type , the piston is in open position where pressurized air is passed on actuator to make it close.

- Normally Close: In Normally Close type, the piston is in close position in unpressurized state where a pressurized air is passed on actuator to make it open.

- Double Acting: A Double acting actuator is monted on the top to provide the piston to operate in both direction.

SALIENT FEATURES

- Actuator mounted on Angle Seat Valve is equipped with NAMUR for easily mounting of Solenoid valve.

- The Maximum temperature range for ‘FLOWON’ Angle Seat Valve is 230 Celcius by providing high temperature resistant seat.

- ‘FLOWON’ Angle Seat Valve is designed to give Excellent flowrate with minimal pressure loss.

- As the piston is fully retracted, the water hammer problem is completely eliminated and the backflow is also restricted.

- Actuator is made up of Stainless steel unlike plastic to withstand the Vibration caused due to operation of valve.

.

TECHNICAL SPECIFICATIONS & PRODUCT RANGE

- Actuator: S.S-304 Pressure Die cast

- BODY: ASTM A 351 GR. CF8 / CF8M / CF3M (On Request)

- Working Parts: S.S-304 / S.S-316 / S.S-316L.

- Seat: PTFE, CFT.

- Temperature: Up to 180⁰ C (Higher temperature on request)

- Pressure Rating: 16 bar maximum

- Leakage: Tight Shutoff

- End Connection: Screwed End (BSPF, NPTF) & Flanged End

- Size range: ½” to 5”.